Covid-19 puts Poland’s logistics and transport groups to the test

Roula Khalaf, Editor of the FT, selects her favourite stories in this weekly newsletter.

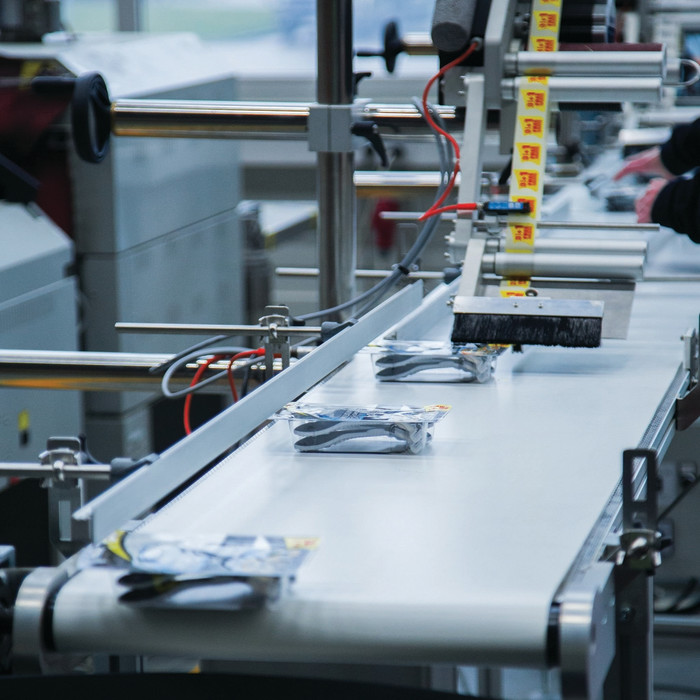

When Poland went into lockdown to fight coronavirus, Antoni Zbytniewski’s work was transformed overnight. Amid fears of food shortages, customers flocked to supermarkets to stock up on essentials. And logistics groups, such as Mr Zbytniewski’s employer, Raben, were suddenly faced with the task of satisfying an enormous surge in demand.

“We had to handle gigantic volume growth overnight with the same resources,” says Mr Zbytniewski, a manager in Raben’s fresh foods logistics business. In some cases, he adds, demand doubled from one day to the next, before falling to about 15 per cent below pre-crisis levels in April as the panic among shoppers subsided.

“Normally we prepare for volume peaks, such as Christmas and Easter, for several months,” he says. “This was not the case with Covid-19. We had to have very intense communications with our customers about what was possible and what was not.”

It was not just wild fluctuations in demand that companies like Raben had to deal with. After Poland closed its borders on March 15 to stem the spread of the pandemic, queues of up to 40km quickly built up on its borders, as Polish citizens rushed to get home. ID and temperature checks to catch returnees who might be infected by the virus slowed traffic dramatically.

Queueing times lasted up to 18 hours, causing chaos to logistics groups’ supply chains. “We had two weeks where we had a lot of issues,” says Lukasz Lubanski, who oversees Raben’s German-Polish trade routes.

“Our network is set up so that we send hundreds of trucks a day like shuttles between different points,” he adds. If a driver is stuck in a queue for 10 hours, the whole chain is broken.”

Two months on, the chaos on Poland’s borders and roads has subsided. But the disruption to the business models of Poland’s logistics and transport companies — one of the country’s big economic success stories — remains.

Jan Buczek, head of the ZMPD, a trade body for Polish transport groups, says surveys of its members showed that the lockdowns introduced to fight Covid-19 had cut business volumes by more than 40 per cent: “But I personally, intuitively, think that this fall was even more than 50 per cent,” he adds.

Companies serving the automotive sector have been particularly hard hit. Like much of central Europe, Poland is home to many groups providing components for Germany’s giant carmakers. With car plants brought to a standstill, however, demand for companies to ferry components between them has plummeted.

Big players like Raben have to some extent been able to mitigate the drastic fall in automotive business lines with steadier revenues in other areas of its business. The company has adapted to the changes wrought by the crisis by starting to ferry consignments of some goods directly to end customers, rather than to such retailers as supermarkets, garden centres and DIY shops.

But for smaller players, switching tack can be tricky. “Quite often logistics groups are highly specialised,” notes Bartosz Marcinkowski, a partner at DZP, a firm specialising in corporate and M&A law. “It is not easy to switch from [transporting] parts of machines to webcams.”

Given such pressures, Piotr Arak, director of the Polish Economic Institute, a government-backed think-tank, says Poland’s transport sector is likely to undergo a bout of consolidation, as smaller players go bankrupt in the coming months.

There is a “high level of fragmentation” in transport, “with a lot of small companies working on small margins, which meant they could be very competitive on the EU market,” he says. “Many of these companies will need to merge in order to be profitable in the coming years.”

Editor’s note

The Financial Times is making key coronavirus coverage free to read to help everyone stay informed.

Others see opportunities for the sector. Mr Lubanski says he expects the disruption experienced by European companies with complex international supply chains to result in them bringing some production back from Asia to Europe. This could provide more business for local logistics groups.

“I think a lot of European enterprises will start to produce in safe places from a lead time, security and production perspective,” he suggests. “Poland, Ukraine and Belarus and the rest of the CEE countries will do well.”

Mr Buczek says he is hopeful that the industry could emerge stronger from the crisis, even if it brings pain in the short term. “Up until now, every crisis strengthened us, because it caused a certain type of selection,” he argues.

“Those that couldn’t cope collapsed, and those that could gained experience and new energy, and moved forwards,” he says. “After this crisis, maybe not immediately, but definitely, we will try to build up our position again.”

Comments